Heliums kølige rejse for at afkøle en partikelaccelerator

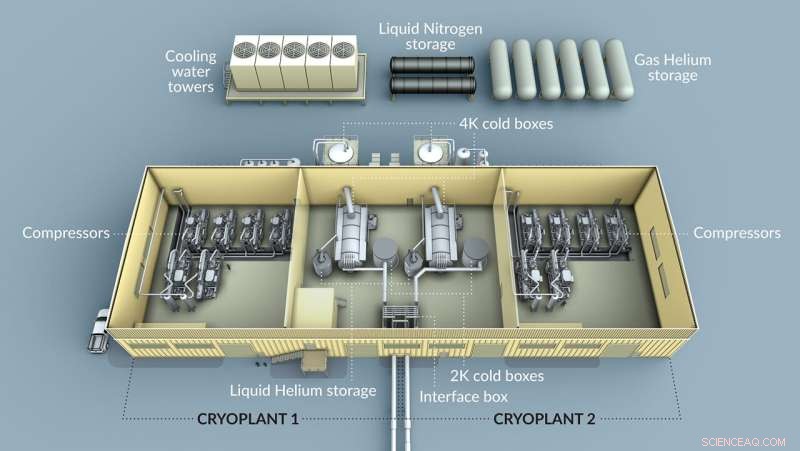

Et skematisk billede af LCLS-II kryoplanten. Kredit:Greg Stewart/SLAC National Accelerator Laboratory

I dag tager det kun halvanden time at gøre en superledende partikelaccelerator på Energiministeriets SLAC National Accelerator Laboratory koldere end det ydre rum.

"Nu klikker du på en knap, og maskinen får fra 4,5 Kelvin ned til 2 Kelvin," sagde Eric Fauve, direktør for Cryogenic-teamet hos SLAC.

Selvom processen nu er fuldt automatiseret, tog det seks år at designe, bygge, installere og starte et indviklet system at få denne accelerator, kaldet LCLS-II, til 2 Kelvin eller minus 456 grader Fahrenheit.

Den originale LCLS, eller Linac Coherent Light Source, accelererer elektroner for i sidste ende at producere røntgenstråler, der bruges i atom- og molekyle-probing-eksperimenter. LCLS-II vil fungere sideløbende med LCLS. Men i modsætning til LCLS, som bruger kobberdele ved stuetemperatur til at accelerere elektroner, anvender LCLS-II-opgraderingen superledende kryomoduler. Disse kryomoduler giver elektroner energi mere effektivt, hvilket vil hjælpe med at generere kraftigere røntgenimpulser for at udvide eksperimentelle muligheder på tværs af felter.

Men mens LCLS kan fungere ved stuetemperatur, skal LCLS-II afkøles til 2 Kelvin, kun 4 grader Fahrenheit over det absolutte nulpunkt, for at blive superledende.

Og det betød, at SLAC havde brug for et hold til at fokusere på kolde ting.

Samling af et hold til at samle en kryoplante

Før LCLS-II afkøles, var der ingen gruppe dedikeret til kryogenik på SLAC.

"Vores største udfordring var, at det var første gang, vi gjorde dette med et nyt hold," sagde Fauve.

LCLS-II Cryogenic-teamet, der nu består af 20 operatører og ingeniører, blev dannet i 2016 hos SLAC for at konstruere det anlæg, der køler acceleratoren:et kryogenanlæg.

"Dette er et kompliceret system med mange undersystemer, der arbejder sammen," sagde Viswanath Ravindranath, ledende kryogen procesingeniør for LCLS-II.

SLAC arbejdede tæt sammen med ingeniører fra DOE's Fermi National Accelerator Laboratory og Jefferson National Accelerator Facility samt førende kryogene virksomheder til at designe og indkøbe materialer til kryoplanten.

"Dette samarbejde gjorde det muligt for LCLS-II-projektet at drage fordel af de bedste kryogene ressourcer inden for DOE-laboratorierne og andre steder," sagde Fauve.

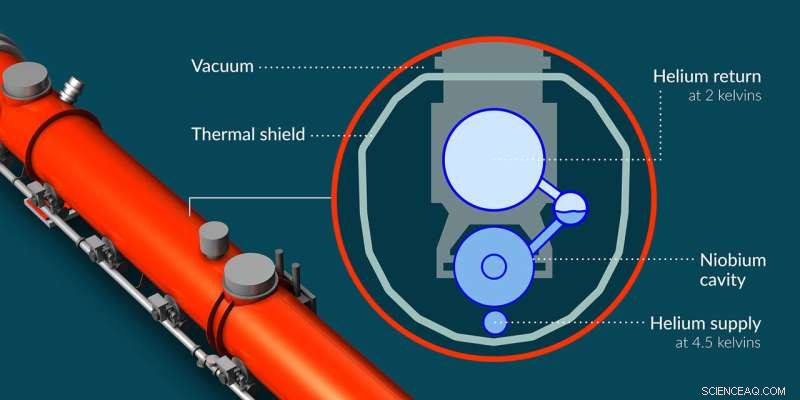

Et tværsnit af LCLS-II acceleratoren, der viser, hvor flydende og gasformigt helium strømmer ind og ud af systemet. Kredit:Greg Stewart/SLAC National Accelerator Laboratory

Kryoplanten fyldes med helium, som afkøles og derefter pumpes til LCLS-II. Mens hvert andet grundstof fryser under 4 Kelvin, kan helium forblive en væske, og ved 2 Kelvin bliver helium superflydende, hvilket betyder, at det flyder uden viskositet. Dette faktum og superfluid heliums evne til at lede varme bedre end noget andet kendt stof, gør det til det perfekte kølemiddel til at køle en superledende accelerator ned.

Before the cooling begins, trailers piled with hotdog-shaped tanks deliver gaseous helium at ambient temperature (about 300 Kelvin) to the cryoplant's outdoor storage tanks. The cryoplant requires a total of four metric tons of helium.

But this helium arrives impure. Any impurities will eventually freeze and clog the system, so first purifiers must trap any moisture or unwanted gases, such as nitrogen, to achieve 99.999% helium.

After purification, compressors raise the helium's pressure. The pressure and temperature of a gas are coupled:as pressure decreases, temperature also decreases. So, while helpful later, this incidentally raises helium's temperature to 370 Kelvin.

Following compression, five large towers containing cooling water are used to lower helium's temperature back down to 300 Kelvin. The gas then enters the cryoplant's 4K cold box, which is a giant, uber-complicated helium refrigerator.

In the cold box, liquid nitrogen running 77 Kelvin knocks the helium down from 300 Kelvin to 80 Kelvin in a heat exchanger. In this device, the warm helium gas and colder liquid nitrogen travel in opposite directions while separated by a thin metal plate, transferring heat through the plate from the helium to the nitrogen. The plant uses 20 metric tons of liquid nitrogen every other day.

The helium then runs through a set of four turboexpanders. Now the initial gas-compressing step pays off:the turboexpanders expand the high-pressure gas, lowering its pressure enough to bring the helium all the way to 5.5 Kelvin.

However, the helium has more expanding to do before it can leave the cold box. It travels through a valve that has lower pressure on the other side. This lower pressure causes the gas to expand, lowering its pressure and bringing its temperature down to 4.5 Kelvin (hence the name of the 4K cold box), where it becomes a liquid.

This liquid helium is then sent through pipes to the accelerator's cryomodules, where it cools the machine to 4.5 Kelvin.

Once the 4K cold box was up and running, it took the Cryogenic team one week to cool LCLS-II from room temperature to 4.5 Kelvin, which it reached for the first time on March 28, 2022. But that's not cold enough!

Colder still

To reach 2 Kelvin, the 4.5 Kelvin helium undergoes yet another (final) expansion through a valve in the accelerator's cryomodules. Again, the lower pressure on the other side of the valve causes helium's pressure to drop. This cools helium to the goal temperature of 2 Kelvin.

Creating the low pressure inside the cryomodule is a feat in itself.

"The magic happens when it goes through that valve, but only because we have a train of cold compressors that maintains the pressure in the cryomodule at very low pressure," Fauve said. This set of five compressors stationed after the valve create the pivotal pressure difference on either side of the valve.

After months of turning on and configuring this cooling system, LCLS-II finally reached 2 Kelvin on April 15.

"Everything was possible because of all the hard work over the years from so many smart and dedicated people," said Swapnil Shrishrimal, cryogenic process and controls engineer for LCLS-II. "Being a small team, as well as a young team, we are very proud of the system we commissioned."

When the electron beam is on and being accelerated by the cryomodules, the 2 Kelvin helium will absorb heat from the accelerator, boil, and turn back into gas. That gas is injected back into the 4K cold box to help cool warmer helium.

"We don't want to waste the cooling capacity, so we try to recover as much of it as possible," Ravindranath said. The system recycles the helium, which is expensive, although essential for long-term operation.

The Cryogenic team actually built two cryoplants, which share a building, but LCLS-II only uses one. The second cryoplant will support planned upgrades to LCLS-II. When both cryoplants are on they will use approximately 10 megawatts of electrical power.

Only four other cryoplants in the United States cool this much helium to 2 Kelvin. Thomas Jefferson National Accelerator Facility and Fermi National Accelerator Laboratory, which both house cryoplants of similar magnitude, supported SLAC's design and procurement of equipment. SLAC collaborated with Oak Ridge National Laboratory, Brookhaven National Laboratory, and CERN as well.

"The years of expertise and support of our partner labs allowed us to do this," Shrishrimal said. Fauve also credits the team's success to their extensive planning and dedication. The entire Cryogenic team stayed on site during the pandemic to continue bringing the plant to life.

"Even when SLAC was shut down, if you were at the cryoplant you would not be able to tell the difference before and during COVID," Fauve said, except for the masks and social distancing, of course.

LCLS-II is expected to produce its first X-rays early next year. The Cryogenic team feels confident they will continue to run their very complicated refrigerator with ease.

"It's a pretty nice and easy operation now because everything is automated," Shrishrimal said. + Explore further

Superconducting X-ray laser reaches operating temperature colder than outer space

Varme artikler

Varme artikler

-

Forskere opdager chirale fononer i en 2-D halvlederkrystalAtombevægelsen i et 2-D materiale, wolfram disulfid, er vist i denne animation. I denne fonetilstand (kendt som optisk longitudinal mode eller LO), selenatomer (gul) roterer med uret, mens wolframatom

Forskere opdager chirale fononer i en 2-D halvlederkrystalAtombevægelsen i et 2-D materiale, wolfram disulfid, er vist i denne animation. I denne fonetilstand (kendt som optisk longitudinal mode eller LO), selenatomer (gul) roterer med uret, mens wolframatom -

Innovativ lysleveringsteknik forbedrer biosensorerEn ny end-fire injektionsteknik bruger en bølgeleder (W), der er direkte forbundet til kanten af mikrodisken. Et fænomen kendt som laser-tid-vending skaber en laser, der absorberer lys i stedet for

Innovativ lysleveringsteknik forbedrer biosensorerEn ny end-fire injektionsteknik bruger en bølgeleder (W), der er direkte forbundet til kanten af mikrodisken. Et fænomen kendt som laser-tid-vending skaber en laser, der absorberer lys i stedet for -

Optagelse af højtryk i diamantkapslerEn perspektivisk tegneserietegning af nanostrukturerede diamantkapsler (NDCer) med højtryksargon-nanodomæner indlejret i matrixen. Moderne diagnostiske prober såsom hårde/bløde røntgenstråler, ultravi

Optagelse af højtryk i diamantkapslerEn perspektivisk tegneserietegning af nanostrukturerede diamantkapsler (NDCer) med højtryksargon-nanodomæner indlejret i matrixen. Moderne diagnostiske prober såsom hårde/bløde røntgenstråler, ultravi -

Spin polarisering induceret af shear flowTil venstre:polariseringen induceret af hvirvelstrømmen; Til højre:polariseringen induceret af forskydningsstrømmen. Røde og gule pile repræsenterer spin- og momentumretningerne, henholdsvis. Kredit:S

Spin polarisering induceret af shear flowTil venstre:polariseringen induceret af hvirvelstrømmen; Til højre:polariseringen induceret af forskydningsstrømmen. Røde og gule pile repræsenterer spin- og momentumretningerne, henholdsvis. Kredit:S

- USA vil acceptere at fjerne plutoniumaffald fra South Carolina

- Farvede støtter klimaindsats, men få får æren for det

- Hvorfor er fotosyntese vigtig for alle organismer?

- Grafen applikationer i mobil kommunikation

- Genomforskning udfordrer tidligere forståelse af fotosyntesens oprindelse

- Nyt fossilfund kaster lys over, hvordan mennesker lærte at gå