Nano-mekanisk undersøgelse tilbyder ny vurdering af silicium til næste generations batterier

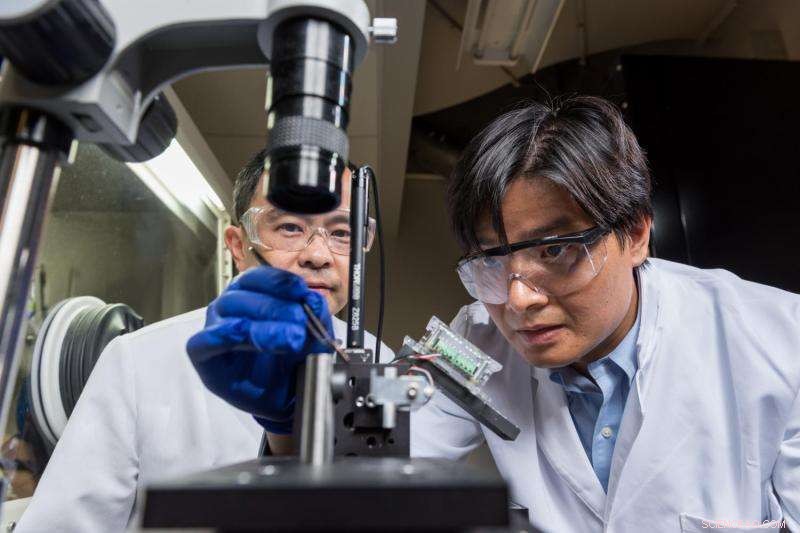

Professor Ting Zhu og adjunkt Suman Xia, begge fra Georgia Tech's Woodruff School of Mechanical Engineering, vise, hvordan en tyndfilmselektrode lavet af amorft silicium blev testet i en tilpasset miljøindenter. For at sikre ordentlig miljøkontrol, prøver indeholdende lithieret silicium blev testet med enheden inde i handskerummet vist i baggrunden. Kredit:Rob Felt, Georgia Tech

En detaljeret nano-mekanisk undersøgelse af mekaniske nedbrydningsprocesser i siliciumstrukturer, der indeholder forskellige niveauer af lithiumioner, giver gode nyheder for forskere, der forsøger at udvikle pålidelige næste generation genopladelige batterier ved hjælp af siliciumbaserede elektroder.

Anoder - de negative elektroder - baseret på silicium kan teoretisk opbevare op til ti gange flere lithiumioner end konventionelle grafitelektroder, gør materialet attraktivt til brug i højtydende lithium-ion-batterier. Imidlertid, materialets skørhed har afskrækket bestræbelser på at bruge rent silicium i batterianoder, som skal modstå dramatiske volumenændringer under opladnings- og afladningscyklusser.

Ved at bruge en kombination af eksperimentelle og simuleringsteknikker, forskere fra Georgia Institute of Technology og tre andre forskningsorganisationer har rapporteret overraskende høj skadetolerance i elektrokemisk lithierede siliciummaterialer. Arbejdet tyder på, at anoder udelukkende af silicium kan være kommercielt levedygtige, hvis batteriladningsniveauet holdes højt nok til at holde materialet i dets duktile tilstand.

Støttet af National Science Foundation, forskningen er rapporteret 24. september i tidsskriftet Naturkommunikation .

"Silicon har en meget høj teoretisk kapacitet, men på grund af de opfattede mekaniske problemer, folk har været frustrerede over at bruge det i næste generations batterier, " sagde Shuman Xia, en assisterende professor ved George W. Woodruff School of Mechanical Engineering ved Georgia Tech. "Men vores forskning viser, at lithieret silicium ikke er så skørt, som vi måske havde troet. Hvis vi arbejder omhyggeligt med det operationelle vindue og udledningsdybden, vores resultater tyder på, at vi potentielt kan designe meget holdbare siliciumbaserede batterier."

Lithium-ion-batterier bruges i dag i en lang række applikationer fra håndholdte mobile enheder op til bærbare computere og elektriske køretøjer. En ny generation af højkapacitetsbatterier kunne lette udvidede transportanvendelser og storskalalagring af elektricitet produceret af vedvarende kilder.

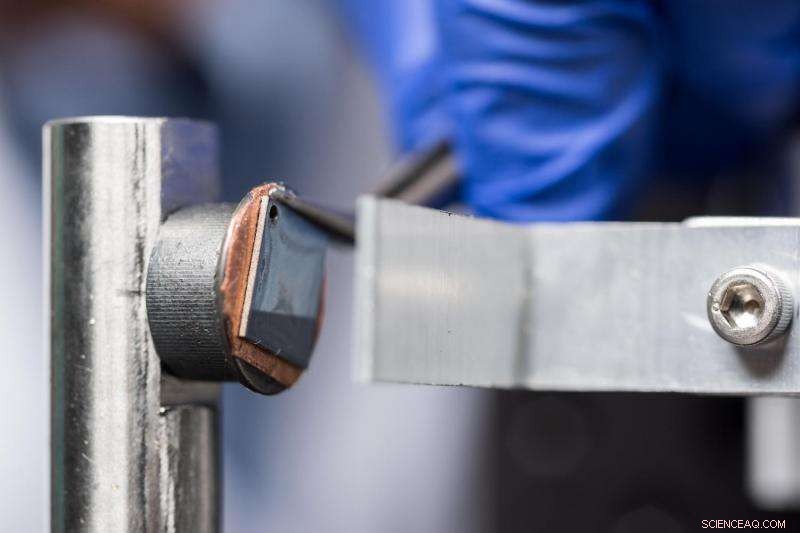

Der er vist detaljer om en tilpasset miljøindenter, der bruges til at teste tyndfilmselektroder lavet af amorft silicium. Enheden blev brugt til at udvikle en detaljeret nano-mekanisk undersøgelse af mekaniske nedbrydningsprocesser i tynde siliciumfilm. Kredit:Rob Felt, Georgia Tech

Udfordringen er at få flere lithium-ioner ind i batteriernes anoder og katoder. Nutidens lithiumbatterier bruger grafitanoder, men silicium er blevet identificeret som et alternativ, fordi det kan lagre væsentligt flere lithiumioner pr. atom. Imidlertid, lagring af disse ioner giver en volumenændring på op til 280 procent, forårsager stress, der kan knække anoder lavet af rent silicium, fører til væsentlig forringelse af ydeevnen. En strategi er at bruge en komposit af siliciumpartikler og grafit, men det realiserer ikke det fulde potentiale af silicium til at øge batterikapaciteten.

I et forsøg på at forstå, hvad der skete med materialerne, forskerholdet brugte en række systematiske nano-mekaniske test, understøttet af simuleringer af molekylær dynamik. For at lette deres studie, de brugte silicium nanotråde og elektrokemiske celler indeholdende siliciumfilm, der var omkring 300 nanometer i tykkelse.

Forskerne studerede den stress, der frembringes af lithiation af silicium tynde film, and used a nanoindenter - a tiny tip used to apply pressure on the film surface - to study crack propagation in these thin films, which contained varying amounts of lithium ions. Lithium-lean silicon cracked under the indentation stress, but the researchers were surprised to find that above a certain concentration of lithium, they could no longer crack the thin film samples.

Using unique experimental equipment to assess the effects of mechanical bending on partially lithiated silcon nanotires, researchers led by Professor Scott Mao at the University of Pittsburgh studied the nanowire damage mechanisms in real-time using a transmission electron microscope (TEM). Their in-situ testing showed that the silicon cores of the nanowires remained brittle, while the outer portion of the wires became more ductile as they absorbed lithium.

"Our nanoindentation and TEM experiments were very consistent, " said Xia. "Both suggest that lithiated silicon material becomes very tolerant of damage as the lithium concentration goes above a certain level - a lithium-to-silicon molar ratio of about 1.5. Beyond this level, we can't even induce cracking with very large indentation loads."

Ting Zhu, a professor in Woodruff School of Mechanical Engineering at Georgia Tech, conducted detailed molecular dynamics simulations to understand what was happening in the electrochemically-lithiated silicon. As more lithium entered the silicon structures, han fandt, the ductile lithium-lithium and lithium-silicon bonds overcame the brittleness of the silicon-silicon bonds, giving the resulting lithium-silicon alloy more desirable fracture strength.

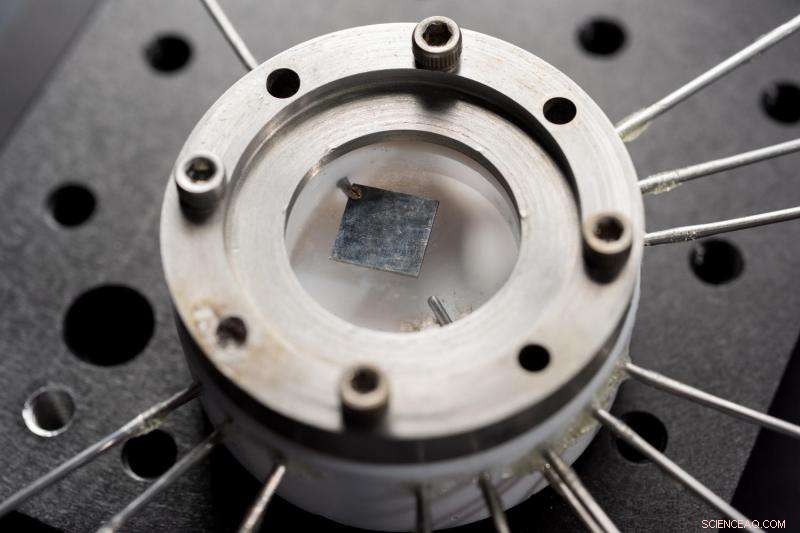

Shown is a sample holder used to test samples of lithiated silicon to determine its nano-mechanical properties. The device was used to develop a detailed nano-mechanical study of mechanical degradation processes in silicon thin films. Credit:Rob Felt, Georgia Tech

"In our simulation of lithium-rich alloys, the lithium-lithium bonds dominate, " Zhu said. "The formation of damage and propagation of cracking can be effectively suppressed due to the large fraction of lithium-lithium and lithium-silicon bonds. Our simulation revealed the underpinnings of the alloy's transition from a brittle state to a ductile state."

Using the results of the studies, the researchers charted the changing mechanical properties of the silicon structures as a function of their lithium content. By suggesting a range of operating conditions under which the silicon remains ductile, Xia hopes the work will cause battery engineers to take a new look at all-silicon electrodes.

"Our work has fundamental and immediate implications for the development of high-capacity lithium-based batteries, both from practical and fundamental points of view, " he said. "Lithiated silicon can have a very high damage tolerance beyond a threshold value of lithium concentration. This tells us that silicon-based batteries could be made very durable if we carefully control the depth of discharge."

I det fremtidige arbejde, Xia and Zhu hope to study the mechanical properties of germanium, another potential anode material for high-rate rechargeable lithium-ion batteries. They will also look at all-solid batteries, which would operate without a liquid electrolyte to shuttle ions between the two electrodes. "We hope to find a solid electrolyte with both high lithium ion conductivity and good mechanical strength for replacing the current liquid electrolytes that are highly flammable, " Zhu said.

"The research framework we have developed here is of general applicability to a very wide range of electrode materials, " Xia noted. "We believe this work will stimulate a lot of new directions in battery research."

Sidste artikelDNA-baserede nanoenheder til molekylær medicin

Næste artikelForskere bygger en skruenøgle 1,7 nanometer bred

Varme artikler

Varme artikler

-

Kemikere udvikler ny teknik til nanostruktursamlingEn kunstnerisk gengivelse af en superpartikel dannet af selvsamlende nanoroder. Kredit:Dustin S. LaMontagne Et team af forskere fra University of Florida afdeling for kemi har udviklet en ny tekni

Kemikere udvikler ny teknik til nanostruktursamlingEn kunstnerisk gengivelse af en superpartikel dannet af selvsamlende nanoroder. Kredit:Dustin S. LaMontagne Et team af forskere fra University of Florida afdeling for kemi har udviklet en ny tekni -

At lave grafen i dit køkkenAtomopløsning, scanning transmission elektronmikroskop billede af en del af et nanoark af shear eksfolieret grafen. De lyse klatter (angivet med pilen) er kulstofatomer. Kredit:CRANN/SuperSTEM Gra

At lave grafen i dit køkkenAtomopløsning, scanning transmission elektronmikroskop billede af en del af et nanoark af shear eksfolieret grafen. De lyse klatter (angivet med pilen) er kulstofatomer. Kredit:CRANN/SuperSTEM Gra -

Nyt nanomateriale giver løfte i bøjeligt, bærbare elektroniske enhederMeget ledende ultratynd film på huden mellem clips. Kredit:Sam Yoon/ Korea University En ultratynd film, der er både gennemsigtig og stærkt ledende over for elektrisk strøm, er blevet fremstillet

Nyt nanomateriale giver løfte i bøjeligt, bærbare elektroniske enhederMeget ledende ultratynd film på huden mellem clips. Kredit:Sam Yoon/ Korea University En ultratynd film, der er både gennemsigtig og stærkt ledende over for elektrisk strøm, er blevet fremstillet -

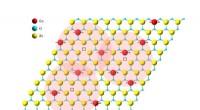

Forskere skaber verdens tyndeste magnetIllustration af magnetisk kobling i et kobolt-doteret zinkoxid monolag. Rød, blå, og gule kugler repræsenterer kobolt, ilt, og zinkatomer, henholdsvis. Kredit:Berkeley Lab Udviklingen af en ultr

Forskere skaber verdens tyndeste magnetIllustration af magnetisk kobling i et kobolt-doteret zinkoxid monolag. Rød, blå, og gule kugler repræsenterer kobolt, ilt, og zinkatomer, henholdsvis. Kredit:Berkeley Lab Udviklingen af en ultr

- Forskere tog afsted for at udforske nye antarktiske økosystemer

- Hvorfor dens menneskelige natur at ignorere vores instinkter

- ATLAS -eksperimentet observerer lys, der spreder lys

- Hvad er afstanden fra solen til kviksølv?

- Champagne i rummet:Zero-G flaske lader turister drikke boblende

- 2020 var Jordens næstvarmeste år, lige bag 2016