Picoscale præcision gennem ultratynd film piezoelektricitet

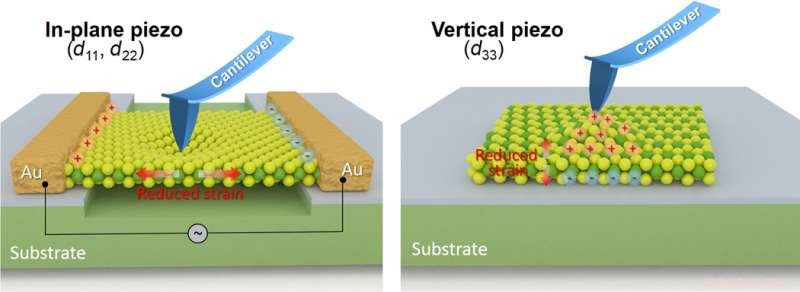

Fig. 1. Skematisk illustration af lokal karakterisering af piezoelektricitet i planet og vertikal piezoelektricitet. Piezoelektricitet i flyet (piezo) ( d 11 , d 22 ) af ultratynde materialer er den plane elektromekaniske paradfærd, hvor den påførte spænding og det producerede piezoelektriske potentiale er placeret i det blotlagte gitterplans in-plan. Vertikal piezoelektricitet ( d 33 ) fokus på elektromekanisk interaktion fandt sted i den lodrette akse, som er vinkelret på overfladen af materialer. Deformationsaktuatoren med høj præcision kan implementeres ved hjælp af nøjagtig positionering af materialeoverfladen ved lodret omvendt piezoelektricitet. Kredit:X. Wang, X. Han, H. Zhu, L. Sun, W. Fu, X. Wang, L. C. Hoong, H. Wang, Q. Zeng, W. Zhao, J. Wei, Z. Jin, Z. Shen, J. Liu, T. Zhang, Z. Liu, Subatomisk deformation drevet af vertikal piezoelektricitet fra CdS ultratynde film. Sci. Adv. 2, e1600209 (2016). Copyright © 2016 Forfatterne, nogle rettigheder forbeholdt; eksklusiv licenstager American Association for the Advancement of Science. Distribueret under en Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). DOI:10.1126/sciadv.1600209.

Piezoelektricitet ( aka den piezoelektriske effekt) forekommer i visse materialer - krystaller (især kvarts), noget keramik, knogle, DNA, og en række proteiner – når påføring af mekanisk stress eller vibration genererer elektrisk ladning eller vekselstrøm (AC) spænding, henholdsvis. (Omvendt, piezoelektriske materialer kan vibrere, når vekselspænding påføres dem.) Den piezoelektriske effekt har en betydelig række anvendelser, herunder lydproduktion og detektering, generering af højspændinger og elektroniske frekvenser, atomopløsning billeddannelsesteknologier (f.eks. scanningstunneling og atomkraftmikroskopi), og aktuatorer til meget nøjagtig positionering af objekter i nanoskala - den sidste er afgørende for grundforskning og industrielle anvendelser. Når det er sagt, Subatomisk skalapositionering giver stadig en række udfordringer. For nylig, imidlertid, forskere ved Nanyang Technological University, Singapore, det kinesiske videnskabsakademi, Suzhou, og Duke University, Durham demonstrerede lodret piezoelektricitet på atomær skala (tre til fem rumgitre) ved hjælp af ultratynde cadmiumsulfid (CdS) film. Forskerne bestemte en lodret piezoelektrisk koefficient ( d 33 ) tre gange så meget som bulk CdS ved brug af in situ scanning Kelvin kraftmikroskopi og enkelt og dobbelt ac resonanssporing piezoelektrisk kraftmikroskopi, får dem til at konkludere, at deres resultater har en række kritiske roller i designet af næste generations sensorer og mikroelektromekaniske enheder.

Prof. Zheng Liu diskuterede papiret, at han, Dr. Ting Zhang og deres kolleger udgivet i Videnskabens fremskridt , beskriver en række udfordringer, de stod over for, begyndende med at bruge kemisk dampaflejring til at syntetisere 2~3 nm cadmiumsulfid (CdS) tynde film. "Den lodrette piezoelektricitet, eller d 33 , er nøgleparameteren i piezoelektriske materialer til fremstilling af aktuatorer, der bruges til at positionere objekter med ekstrem nøjagtighed – ned til atomær skala i en bred vifte af banebrydende udstyr såsom atomkraftmikroskopi og scanning tunneling mikroskopi, " fortæller Liu Phys.org . "I øvrigt, højtydende ultratynde piezoelektriske materialer er afgørende for at konstruere ultrahøj opløsning og fleksible elektromekanisk koblede enheder."

Forud for denne undersøgelse, Liu påpeger, kun få undersøgelser rapporterede syntesen af atomare tynde piezoelektriske materialer ved en vådkemisk metode, eksempler herpå omfatter CdS og cadmiumselenid (CdSe) nanoblodplader. "Det er en betydelig udfordring at producere højkvalitets og atomtynde piezoelektriske materialer, " tilføjer han. "I denne forskning, hovedudfordringen ved at syntetisere ultratynde piezoelektriske CdS-film via kemisk dampaflejring" (eller CVD) "ligger i udvælgelsen af prækursorer og hvordan man optimerer reaktionsparametrene, såsom stigende temperatur og tid."

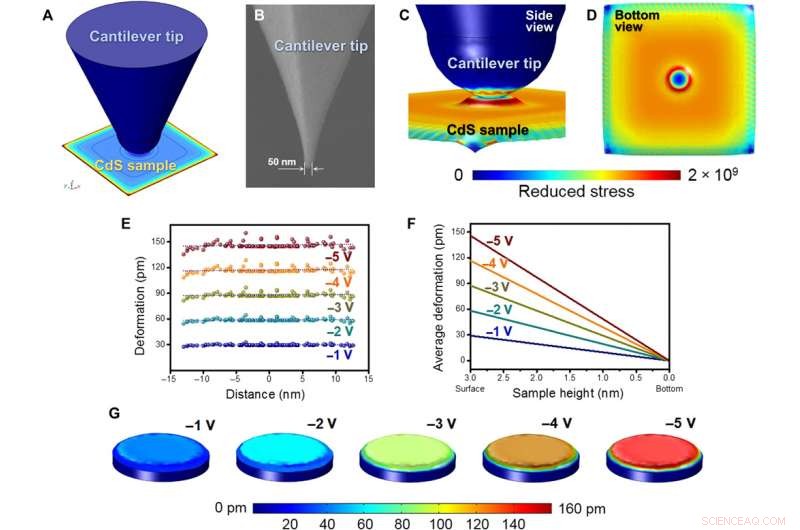

Forskerne stod derefter over for at demonstrere d 33 lodret piezoelektricitet på atomær skala ved hjælp af ultratynde cadmiumsulfid tynde film. "Når tykkelsen af materialer når nanoskalaniveauet, " Liu forklarer, "det er meget svært at verificere den piezoelektriske effekt og bestemme dens værdier på grund af koblingseffekten fra substratet - og overfladegeometrier kan også påvirke målingerne ved atomare grænser." For eksempel, han illustrerer, prøvens overfladeruhed når titusinder af pimeter, som er den samme skala med den vertikale elektromekaniske respons for materialer.

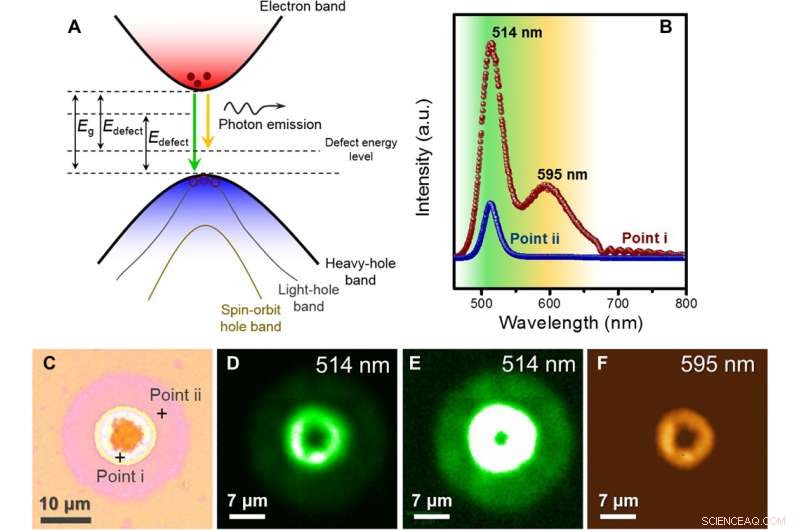

Fig. 3. Spektroskopisk karakterisering af CdS tynd film. (A) Energi ( E ) båndstruktur i nærheden af Γ-punktet i Brillouin-zonen, viser fotonemissionsprocessen. (B og C) PL spektrum af CdS tynd film fra punkt i og ii markeret i (C) med plustegn, viser stærk båndkantemission (506 nm) af CdS ultratynd film og defektrelateret emission (595 nm). (C) Optisk billede af CdS tynd film med en afrundet mikropartikel i midten. a.u., vilkårlige enheder. (D og E) PL-kortlægning ved en emission på 514 nm med en anden skala bar, demonstrerer høj ensartethed og homogenitet af CdS tynde film på ydersiden. (F) PL-kortlægning ved 595-nm-emissionen, hvilket indikerer, at den defekt-relaterede emission kun forekommer ved den tykkere CdS-mikropartikel. Kredit:X. Wang, X. Han, H. Zhu, L. Sun, W. Fu, X. Wang, L. C. Hoong, H. Wang, Q. Zeng, W. Zhao, J. Wei, Z. Jin, Z. Shen, J. Liu, T. Zhang, Z. Liu, Subatomisk deformation drevet af vertikal piezoelektricitet fra CdS ultratynde film. Sci. Adv. 2, e1600209 (2016). Copyright © 2016 Forfatterne, nogle rettigheder forbeholdt; eksklusiv licenstager American Association for the Advancement of Science. Distribueret under en Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). DOI:10.1126/sciadv.1600209.

Til sidst – og minder om udfordringen med at demonstrere d 33 lodret piezoelektricitet på atomær skala ved hjælp af CdS tyndfilm – forskerne skulle bestemme den vertikale piezoelektriske CdS-filmskoefficient med in situ scanning Kelvin kraftmikroskopi (SKFM) og enkelt og dobbelt AC resonanssporing piezoelektrisk kraftmikroskopi (DART-PFM). "Kvaliteten af ultratynde piezoelektriske CdS er nøglen til at opnå en pålidelig vertikal piezoelektrisk koefficient." Liu bemærker. "Nogle karakteriseringsværktøjer som Raman og fotoluminescensspektroskopier kan hjælpe os med at identificere CdS-prøven og bekræfte dens høje kvalitet. på grund af de geometriske vibrationer af CdS-prøverne, karakteriseringen af atomkraftmikroskopi bør udføres omhyggeligt for at sikre, at vores konklusioner er solide." Dette krævede, at forskerne skulle undersøge mange SKFM- og DART-PFM-prøver for at nå frem til en solid konklusion om vertikal piezoelektrisk adfærd i ultratynde CdS-film.

Liu kommenterer, at det krævede innovative teknikker at løse disse udfordringer. "For første gang, vi har med succes syntetiseret højkvalitets atomare tynde CdS-film ved hjælp af CVD, and we demonstrated vertical piezoelectricity of these films at the atomic scale of 3~5 space lattices" (a space, or crystal, lattice being a periodically repeating two- or three-dimensional array of points or particles) "and observed the vertical piezoelectric domains. More importantly, " Liu continues, "our work shows an enhanced vertical piezoelectricity in CdS ultrathin films at a level three times larger than the CdS bulk counterpart, as well as higher than most of traditional piezoelectric materials." These results imply non-trivial piezoelectric behavior at atomic limits for a certain class of materials – which has not yet been well explored – and inspires the search for two-dimensional free-standing layered piezoelectric materials that are only one atom thick.

Liu points out that their findings shed light on the design of next-generation sensors, actuators and microelectromechanical devices, in that piezoelectric materials are the most important component for such devices. Specifikt, he says that their findings provide the opportunity for next-generation sensors and microelectromechanical devices in three ways:

- Flexibility :Ultrathin piezoelectric material materials are naturally like two-dimensional materials in being flexible, allowing them to be conformably used for more complicated electromechanical devices.

- Miniaturization :Ultrathin piezoelectric material materials are a perfect candidate for the fabrication of reduced size, highly integrated devices, especially for mobile phone and wearable devices.

- Inspiration :The study's results will inspire the development of other ultrathin piezoelectric materials, especially two-dimensional piezoelectric materials.

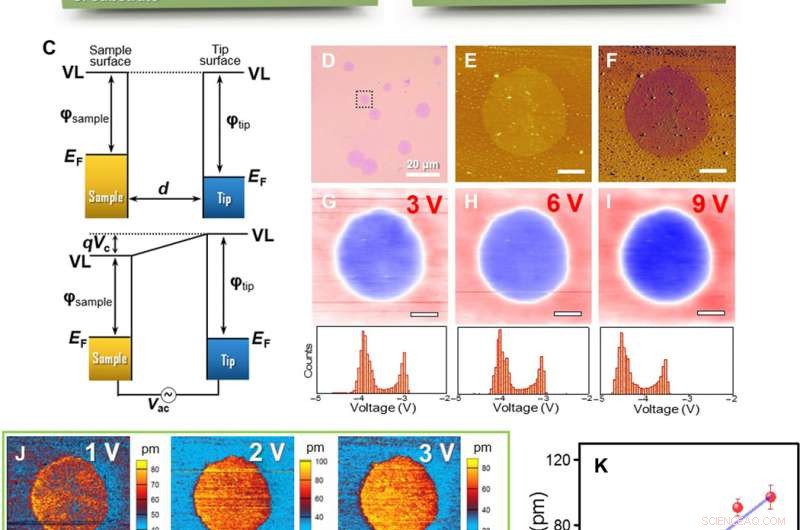

Fig. 4. Noncontact SKFM and standard contact PFM investigation for CdS thin film. (A and B) Schematic illustration of SKFM (A) and PFM (B) measurements. (C) Band diagram of tip and sample when they are electrically separated (top graph) and electrically contacted (bottom graph). d , distance; VL, vacuum levels; q , electronic charge; V c , contact potential difference. (D) Optical image of CdS thin films. (E and F) Topography (E) and phase (F) images observed by SKFM mode for the single CdS thin film marked in (D). (G to I) Corresponding potential mappings with tip voltages of 3, 6, and 9 V, henholdsvis. Insets show histograms of the surface potential distributions. The CdS ultrathin film has a higher positive voltage (~0.9 V) than the substrate, demonstrating that a large amount of charges are accumulated at a CdS thin film after contact PFM scanning. (J) Amplitude images observed by contact PFM technology with tip voltages from 1 to 6 V, showing remarkable inverse piezoelectricity. (K) Average amplitude variations versus applied voltages calculated from (J). Error bars indicate 1 SD. Scale bars, 2 μm (E to J). The linearly fitted line shows that the measured piezoelectric coefficient d eff is ~16.4 pm·V −1 , whereas the vertical piezoelectric coefficient d 33 is ~32.8 pm·V −1 . Credit:X. Wang, X. He, H. Zhu, L. Sun, W. Fu, X. Wang, L. C. Hoong, H. Wang, Q. Zeng, W. Zhao, J. Wei, Z. Jin, Z. Shen, J. Liu, T. Zhang, Z. Liu, Subatomic deformation driven by vertical piezoelectricity from CdS ultrathin films. Sci. Adv. 2, e1600209 (2016). Copyright © 2016 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). DOI:10.1126/sciadv.1600209.

Liu illustrates these points by listing potential examples of such devices – for example, atomically thin piezoelectric devices – and their applications. "For eksempel, using CdS ultrathin films, the most accurate probe or stage ever fabricated may be achievable, allowing researchers and engineers to manipulate atoms or position tips in atomic force, scanning electron and transmission electron microscopy. Med andre ord, CdS ultrathin films will extend our capability to see and manipulate our world in an extreme way." Of more importance, tilføjer han, such ultrathin piezoelectric devices can be integrated into equipment like autocollimators and Michelson interferometers used in, for eksempel, cold atom studies, the verification of the gravitational inverse square law at short range, and even the detection of gravitational waves.

The study also reports the in situ measurement of the ultrathin CdS film vertical piezoelectric coefficient d 33 , determining the film coefficient to be approximately three times larger than that of bulk CdS. "This value is pretty big for atomically thin materials, " Liu explains. "It means that we can get a large voltage change when small pressure or deformation is applied. This makes the material a great candidate constructing sensitive and ultrathin mechanical sensors."

Fig. 6. Simulation of vertical piezoelectricity and subatomic deformation actuator. (A) Three-dimensional image of potential drop on CdS film. (B) Scanning electron microscopy image of a conductive tip for PFM characterization. (C and D) Bottom and side views of stress distribution on CdS film. (E to G) Simulation for subatomic deformation actuator. Different potentials were applied to surface deformation curves (E), mappings (G), and vertical deformation (F) of CdS thin films. Credit:X. Wang, X. He, H. Zhu, L. Sun, W. Fu, X. Wang, L. C. Hoong, H. Wang, Q. Zeng, W. Zhao, J. Wei, Z. Jin, Z. Shen, J. Liu, T. Zhang, Z. Liu, Subatomic deformation driven by vertical piezoelectricity from CdS ultrathin films. Sci. Adv. 2, e1600209 (2016). Copyright © 2016 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). DOI:10.1126/sciadv.1600209.

The researchers concluded that contact piezoresponse force microscopy (PFM) – which uses a conductive tip to apply a highly localized electric field that allows imaging and manipulation of piezoelectric ferroelectric materials – could significantly change the surface potential of a CdS ultrathin film by applying stress to its surface. "Typisk, applying mechanical stress to a piezoelectric material will generate electric charge that accumulates at the surface of the material, which is how we identify the piezoelectric materials, " Liu tells Phys.org . "We therefore believe that this results from piezoelectric polarizations giving rise to a large piezoelectric potential, in turn leading to a remarkable spatial separation of electrons and holes." In this case, electrons generated by the piezoelectric effect will be trapped into the silicon dioxide (SiO 2) dielectric layers, while the holes will be trapped inside the crystal boundary of the CdS films.

The scientists state that their work may pave a way to the synthesis of ultrathin lattice scale nanomaterials using CVD method, which is a low-cost method for producing high quality samples. Ud over, Liu notes, the materials provided by their study will enable the high-integrated and multi-functional devices by simply coating or transferring the film to the device. "For actuator applications, our work will promote next generation actuators with extreme resolution for their potential use in characterization tools such as ultra-high resolution microscopy; for atom manipulation and fabrication; or potentially for the detection of ultra-low deformation in, for eksempel, cold atom studies, verification of the gravitational inverse square law at short range, and even the detection of gravitational waves."

Moving forward, Liu says, the scientists will determine the relationship between the vertical piezoelectric coefficient d 33 and the thickness of CdS at atomic scales. "Well also synthesize other piezoelectric, ferroelectric and layered piezoelectric/ferroelectric ultrathin materials, and explore their electromechanical properties." Based on this material and micro/nano-manufacture technology, the researchers hope to design and fabricate next-generation actuators for accurate positioning of minute objects, such as nanoparticles at subatomic scales, using their novel materials.

Ud over, the large vertical piezoelectric coefficient d 33 makes this material promising to construction of ultrathin and sensitive pressure sensors for detecting miniscule forces. If the low detection limit of sensor reaches to nanoscale levels, the device could monitor single biological cell migration.

"Our study will inspire material scientists to hunt for other non-trivial ultrathin or layered piezoelectric or ferroelectric materials, " Liu tells Phys.org . "Engineers can employ our CdS ultrathin films to design and fabricate novel microelectromechanical systems, " or MEMS, "and nanoelectromechanical systems, " or NEMS, "with high-integration and multi-functionalities, and may benefit when developing cutting-edge scientific instruments. Desuden, " konkluderer han, "novel and flexible consumer electronic devices can be developed based on our study."

© 2016 Phys.org

Varme artikler

Varme artikler

-

Nanodiamonds:En kræftpatients bedste ven?Diamanter betragtes nogle gange som en piges bedste ven. Nu, dette udtryk er ved at få en ny betydning. Ja, diamantpartikler i nanometrisk skala kunne tilbyde en ny måde at opdage kræft langt tidliger

Nanodiamonds:En kræftpatients bedste ven?Diamanter betragtes nogle gange som en piges bedste ven. Nu, dette udtryk er ved at få en ny betydning. Ja, diamantpartikler i nanometrisk skala kunne tilbyde en ny måde at opdage kræft langt tidliger -

En bedre måde at indkapsle øceller til diabetesbehandlingMIT-ingeniører har udtænkt en måde at inkorporere krystalliserede immunsuppressive lægemidler i enheder, der bærer indkapslede øceller, som kunne give dem mulighed for at blive implanteret som en lang

En bedre måde at indkapsle øceller til diabetesbehandlingMIT-ingeniører har udtænkt en måde at inkorporere krystalliserede immunsuppressive lægemidler i enheder, der bærer indkapslede øceller, som kunne give dem mulighed for at blive implanteret som en lang -

Ekstremt stærk nano-twinned ren nikkel med ekstrem fin tvillingtykkelseTypisk mikrostruktur af aflejret NT-Ni med en ekstrem fin tvillingtykkelse. (A) Tredimensionel struktur af NT-Ni sammensat af plan-view og tværsnit af lysfelt TEM-billeder. (B) Fordelinger af tvilling

Ekstremt stærk nano-twinned ren nikkel med ekstrem fin tvillingtykkelseTypisk mikrostruktur af aflejret NT-Ni med en ekstrem fin tvillingtykkelse. (A) Tredimensionel struktur af NT-Ni sammensat af plan-view og tværsnit af lysfelt TEM-billeder. (B) Fordelinger af tvilling -

Verdens første 3D plasmon lineal:Tager 3D-mål for makromolekylerDen rumlige frihed tilvejebragte 3-D plasmonlinealens fem nanorods gør det muligt for den at måle retningen såvel som størrelsen af strukturelle ændringer i en makromolekyleprøve. Kredit:udlånt af P

Verdens første 3D plasmon lineal:Tager 3D-mål for makromolekylerDen rumlige frihed tilvejebragte 3-D plasmonlinealens fem nanorods gør det muligt for den at måle retningen såvel som størrelsen af strukturelle ændringer i en makromolekyleprøve. Kredit:udlånt af P

- Hvordan man kan klare ekstreme varme dage uden at skrue op for aircon-regningerne

- Kulstofrig varm boble opdaget i den planetariske tåge NGC 5189

- Har du den rigtige personlighed til Facebook?

- Laura forudser nu at blive en katastrofal kategori 4-orkan

- Sådan finder du X & Y Aflytninger på en Graphing Calculator

- Kildens troværdighed er nøglen til at afspore falske nyheder