Har du brug for hjælp til at bygge IKEA-møbler? Denne robot kan give en hånd

Et online spil til montering af hylde, udviklet som proof-of-concept. Kredit:University of Southern California

Efterhånden som robotter i stigende grad går sammen om at arbejde med mennesker – fra plejehjem til lagerbygninger til fabrikker – skal de være i stand til proaktivt at tilbyde support. Men først skal robotter lære noget, vi ved instinktivt:hvordan man kan forudse folks behov.

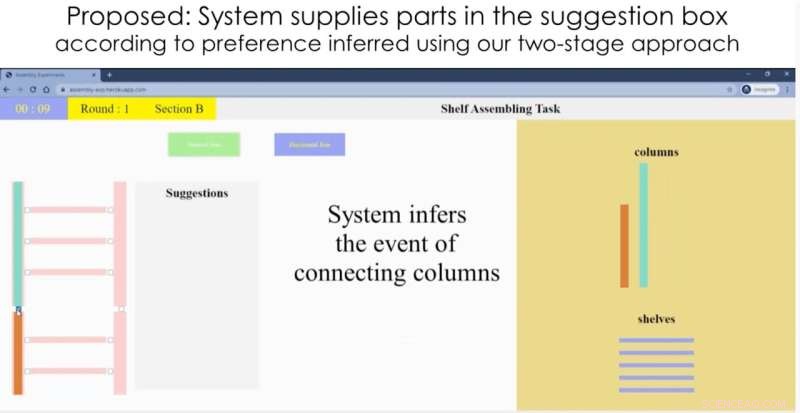

Med det mål i tankerne har forskere ved USC Viterbi School of Engineering skabt et nyt robotsystem, der præcist forudsiger, hvordan et menneske vil bygge en IKEA reol, og derefter giver en hånd med - sørger for den hylde, bolt eller skrue, der er nødvendig for at fuldføre opgaven . Forskningen blev præsenteret på den internationale konference om robotteknologi og automatisering den 30. maj 2021.

"Vi vil have mennesket og robotten til at arbejde sammen - en robot kan hjælpe dig med at gøre tingene hurtigere og bedre ved at udføre understøttende opgaver, som at hente ting," sagde undersøgelsens hovedforfatter Heramb Nemlekar. "Mennesker vil stadig udføre de primære handlinger, men kan overføre simplere sekundære handlinger til robotten."

Nemlekar, en ph.d. studerende i datalogi, vejledes af Stefanos Nikolaidis, en assisterende professor i datalogi, og var medforfatter til papiret sammen med Nikolaidis og SK Gupta, en professor i rumfart, maskinteknik og datalogi, som har Smith International Professorship in Mechanical Engineering.

Tilpasning til variationer

I 2018 lærte en robot skabt af forskere i Singapore berømt at samle en IKEA stol selv. I denne nye undersøgelse sigter USC-forskerholdet mod i stedet at fokusere på menneske-robot-samarbejde.

Der er fordele ved at kombinere menneskelig intelligens og robotstyrke. På en fabrik kan en menneskelig operatør for eksempel kontrollere og overvåge produktionen, mens robotten udfører det fysisk anstrengende arbejde. Mennesker er også mere dygtige til disse besværlige, sarte opgaver, som at vrikke en skrue rundt for at få den til at passe.

The key challenge to overcome:humans tend to perform actions in different orders. For instance, imagine you're building a bookcase—do you tackle the easy tasks first, or go straight for the difficult ones? How does the robot helper quickly adapt to variations in its human partners?

"Humans can verbally tell the robot what they need, but that's not efficient," said Nikolaidis. "We want the robot to be able to infer what the human wants, based on some prior knowledge."

It turns out, robots can gather knowledge much like we do as humans:by "watching" people, and seeing how they behave. While we all tackle tasks in different ways, people tend to cluster around a handful of dominant preferences. If the robot can learn these preferences, it has a head start on predicting what you might do next.

A good collaborator

Based on this knowledge, the team developed an algorithm that uses artificial intelligence to classify people into dominant "preference groups," or types, based on their actions. The robot was fed a kind of "manual" on humans:data gathered from an annotated video of 20 people assembling the bookcase. The researchers found people fell into four dominant preference groups.

In an IKEA furniture assembly task, a human stayed in a “work area” and performed the assembling actions, while the robot brought the required materials from storage area. Credit:University of Southern California

For instance, do you connect all the shelves to the frame on just one side first; or do you connect each shelf to the frame on both sides, before moving onto the next shelf? Depending on your preference category, the robot should bring you a new shelf, or a new set of screws. In a real-life IKEA furniture assembly task, a human stayed in a "work area" and assembled the bookcase, while the robot—a Kinova Gen 2 robot arm—learned the human's preferences, and brought the required materials from a storage area.

"The system very quickly associates a new user with a preference, with only a few actions," said Nemlekar.

"That's what we do as humans. If I want to work to work with you, I'm not going to start from zero. I'll watch what you do, and then infer from that what you might do next."

In this initial version, the researchers entered each action into the robotic system manually, but future iterations could learn by "watching" the human partner using computer vision. The team is also working on a new test-case:humans and robots working together to build—and then fly—a model airplane, a task requiring close attention to detail.

Refining the system is a step towards having "intuitive" helper robots in our daily lives, said Nikolaidis. Although the focus is currently on collaborative manufacturing, the same insights could be used to help people with disabilities, with applications including robot-assisted eating or meal prep.

"If we will soon have robots in our homes, in our work, in care facilities, it's important for robots to infer and adapt to people's preferences," said Nikolaidis. "The robot needs to be a teammate and a good collaborator. I think having some notion of user preference and being able to learn variability is what will make robots more accepted."

Sidste artikelSådan bygger man en bedre vindmøllepark

Næste artikelHvad er advarselsskiltene, før en bygning styrter sammen?

Varme artikler

Varme artikler

-

Mange af New Zealands mest populære websteder bruger mørke mønstre til at manipulere brugere – er…Kredit:Shutterstock Mere end halvdelen af de mest populære New Zealand-websteder manipulerer muligvis besøgende uretfærdigt, ifølge vores seneste forskning i brugen af mørke mønstre på webstede

Mange af New Zealands mest populære websteder bruger mørke mønstre til at manipulere brugere – er…Kredit:Shutterstock Mere end halvdelen af de mest populære New Zealand-websteder manipulerer muligvis besøgende uretfærdigt, ifølge vores seneste forskning i brugen af mørke mønstre på webstede -

Forskere udvikler en mere omfattende metode til akustisk sceneanalyseForudsigelser af lyde blev opnået ved en forbedret metode udviklet af et internationalt hold af forskere. Kredit: IEEE/CAA Journal of Automatica Sinica Forskere har demonstreret en forbedret meto

Forskere udvikler en mere omfattende metode til akustisk sceneanalyseForudsigelser af lyde blev opnået ved en forbedret metode udviklet af et internationalt hold af forskere. Kredit: IEEE/CAA Journal of Automatica Sinica Forskere har demonstreret en forbedret meto -

Spiller spil? Det er en seriøs måde at vinde samfundets opbakning til forandringCitizen Block er en øvelse i kollaborativ lejlighedsplanlægning og design. Kredit:Anthony Duckworth-Smith Hvordan ville du og dine naboer tredoble antallet af husstande i din gadeblok for at holde

Spiller spil? Det er en seriøs måde at vinde samfundets opbakning til forandringCitizen Block er en øvelse i kollaborativ lejlighedsplanlægning og design. Kredit:Anthony Duckworth-Smith Hvordan ville du og dine naboer tredoble antallet af husstande i din gadeblok for at holde -

3 nedbrud, 3 dødsfald rejser spørgsmål om Teslas AutopilotI denne 8. juli, 2018, fil foto, skyer afspejles over virksomhedens logo på motorhjelmen på et Tesla -køretøj uden for et showroom i Littleton, Colo. National Highway Traffic Safety Administration eft

3 nedbrud, 3 dødsfald rejser spørgsmål om Teslas AutopilotI denne 8. juli, 2018, fil foto, skyer afspejles over virksomhedens logo på motorhjelmen på et Tesla -køretøj uden for et showroom i Littleton, Colo. National Highway Traffic Safety Administration eft

- Undersøgelse ser til is for at fremstille nyttige porøse materialer

- Virtuelt gåsystem til genoplevelse af en anden persons rejse

- Perseverance rover lander på Mars i denne uge

- Boligudgifter dæmper beboernes tilfredshed med livet i Los Angeles

- Medarbejdernes frivillighed? Kun hvis du synes, din chef er etisk

- Molekylær ilt detekteret i den nærmeste kvasar